Weighing Station and Tag Marking

The weighing and tag marking are designed to follow the customer's

demand.

Unloading Station

Various types of unloading stations are available; Storing Rack, Walking

Beam and storage Car.

Electrical Control System - Tracking

As for the horizontal system, the complete system is PLC controlled.

Tracking of the coils is based on hook identification readers interconnected

to mill computer system.

Hydraulic System

Where necessary, the movements are hydraulically operated with oil

supply from a SUND BIRSTA central power unit.

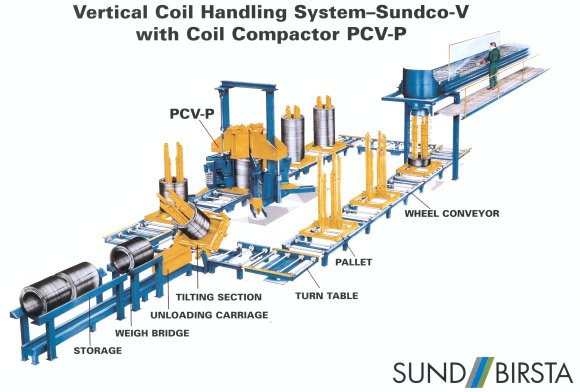

ADVANTAGES OF SUNDCO-V

- Reduced investment due to the simplicity of reform station where

the coils are formed directly onto the pallet.

- Simple design with belt drive and direct shaft driven motors

guarantees low maintenance and costs.

- Easy to extend due to standardised wheel sections.

- The Coil Compactor and the four wire/strap binding units are

designed for easy access to vital components.

- Open view from the operator station, which simplifies the operation.

- Low noise level due to the belt drive of the wheel sections.

- Minimal floor space required for a complete conveying system.

|